- Home

- Products

Products

TVPI® Temperature Vacuum Pressure Impregnation

The specific advantages of the TVPI® tool:

- reproducible and verifiable process

- increased production workflow

- efficient and short production cycle

- drastic reduction of the production and tool costs

- closed process without emission of styrol

- minimized utilization of resin

- impregnation and curing- process in one tool and one step

- with one TVPI® tool all versions of one stator bar set can be produced (upper bar, lower bar, switch bar

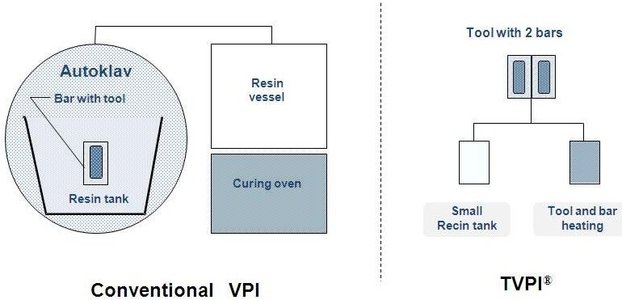

Comparison of the impregnation process:

- Comparing to competing systems the resin consumption is reduced drastically

- Extensive peripherals, such as autoclaves or tempering ovens for curing the bars are not needed because the bars will be cured inside the TVPI® tool

- Parallel operation of multiple TVPI® tools in a small production area is possible

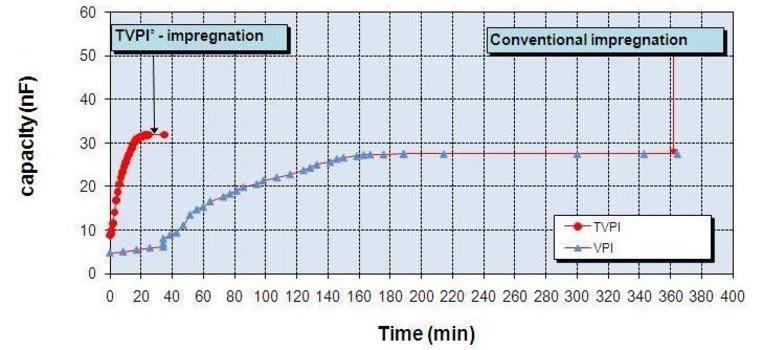

Comparison TVPI® and VPI impregnation circle:

- Depending on the bar geometry, we have a fixed production cycle between 4 to 8 hours. In this case, the daily production (24 hours) of 4 to 6 bars results with one TVPI® tool

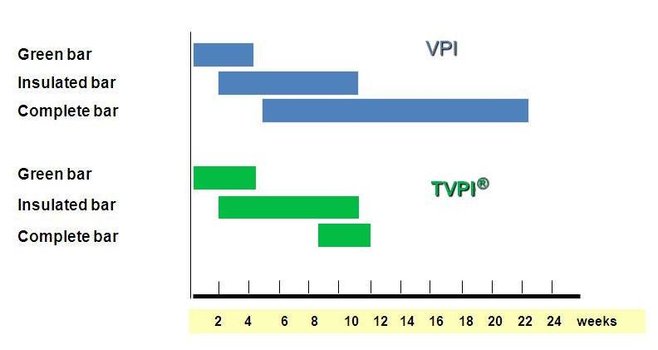

Comparison circle time stator bar set:

- The impregnation time of a complete stator winding can be reduced to a minimum

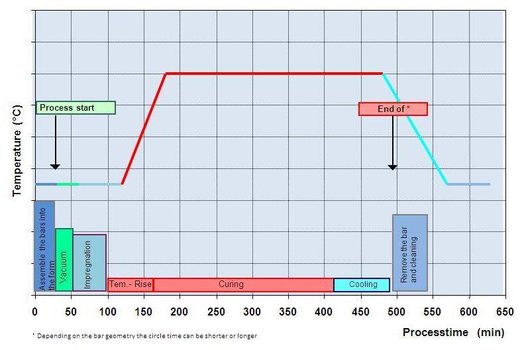

Process over view TVPI® tool:

- The manual effort as well as the manual cleaning process of the tool is reduced to less than 1,5 hour per impregnation of two bars

- Our experience with TVPI® shows that the tangent delta values (tanD) in comparison to the VPI-impregnation are stable in the lower tolerance

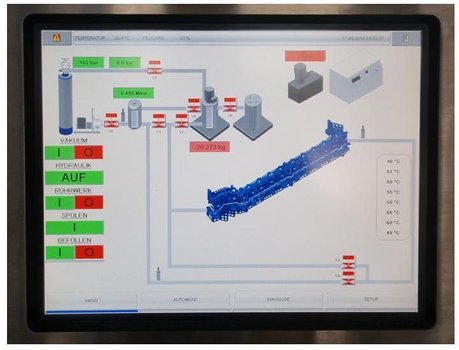

SSI Sensor System for Impregnation

The SSI steers a fully automated impregnation process as well as the complete curing of the stator bars. It also assures continuous supervision, precise control and long-term documentation of the manufacturing process. This will minimize errors and guarantee a manufacturing process which is secured and reproducible. All process steps will be recorded and will be stored as a traceable part data base.

- All process steps (in seconds, minutes and hours) will be recorded and stored on a CF-Card

- The monitoring and control is performed on a touchpad which allows a manual control of the process

- The part data base can be generated and transferred into an existing ERP-System

- In case of expansion needs remote access will be available

- The graphical supervision of the manufacturing process will be facilitated via web interface

- The CAN-Bus system enables the connection to all interface types

The tool design is protected by copyright.

PETT & P.E.T.T. Trade and Industry Products GmbH

Schlossgäßchen 4a

55288 Udenheim

Germany

Phone: +4915155988869

E-Mail: info[at]pp-tip.com